Advancing Industry

Markets

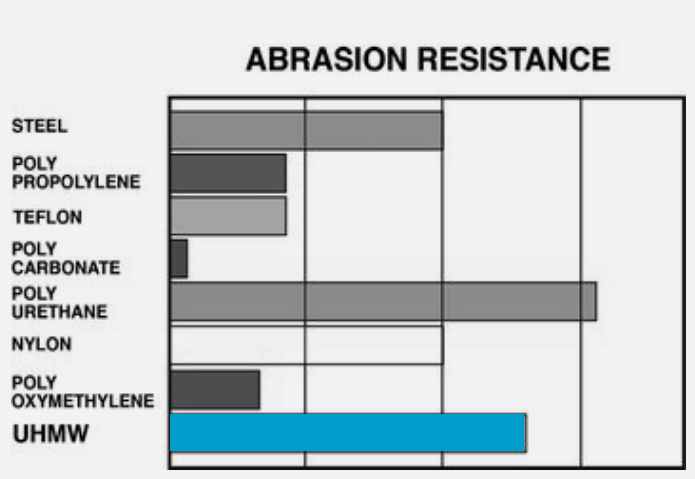

The most durable surface protection of any of the polymers on the market

OceaPoly® is changing the way to manufacture high-performance shallow-draft boats with the introduction of our Kevlar Fiberglass fabric backing. Bonded OceaPoly® is a high-performance alternative to mechanically fastened polymers, providing OEM’s the best solution to meet the needs for efficient production and superior service.

- Airboats

- River Jet Boats

- Landing Crafts

- Drift Boats

- Hard Bottom Inflatables

- Shallow Draft Skiffs

- Lobster Boats

- Pontoon Boats

- Jon Boats

- Hunting Vessels

- Jet Skis & Sea Dos

- Kayaks & Canoes

- Surveillance Crafts

Riverne Assault Crafts

Technology

A revolutionary technology advancing the boating industry across the globe.

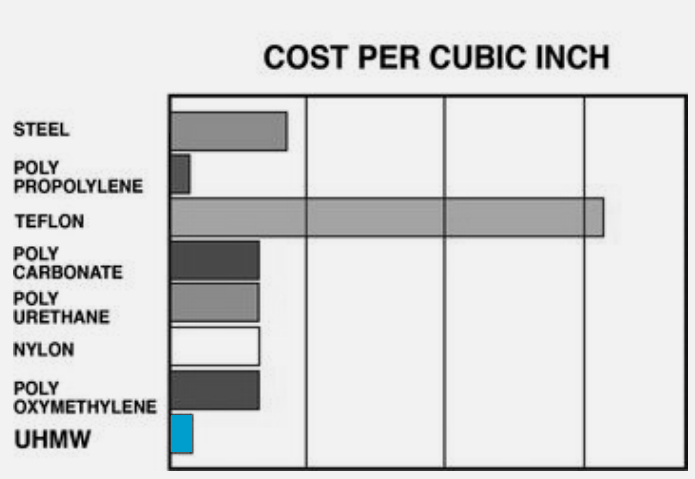

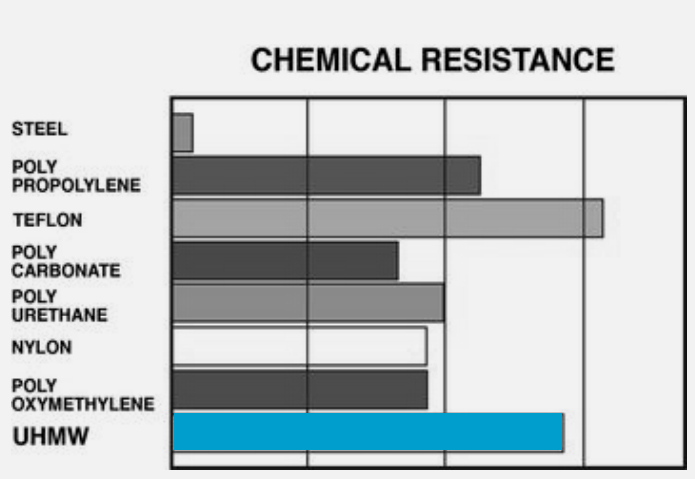

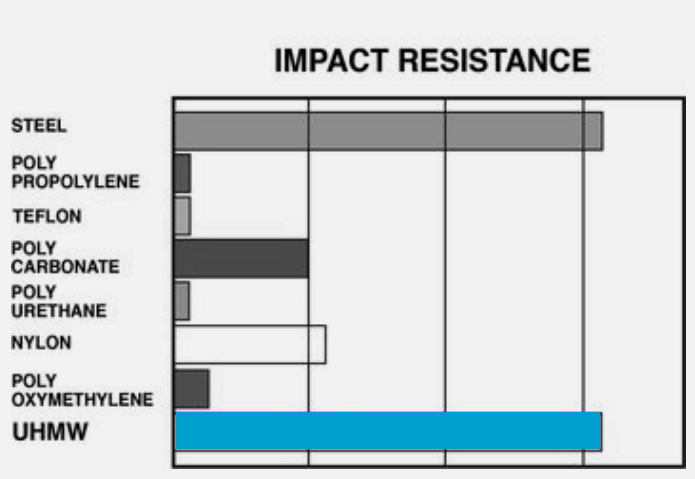

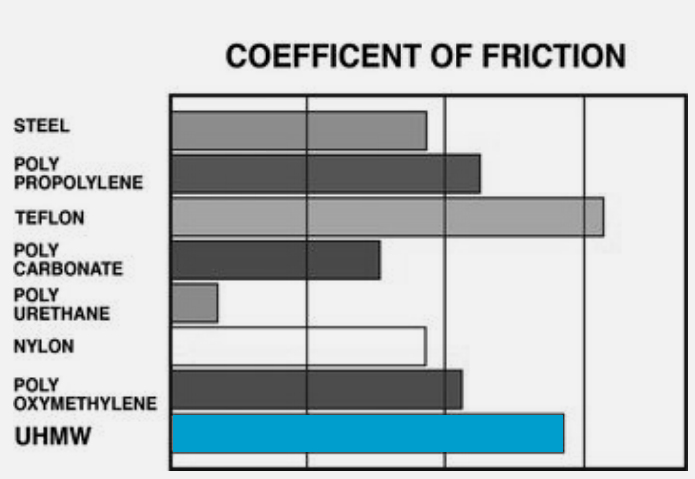

Standard lower grade HDPE currently used by many shallow draft boat builders' wears 4 times faster and has 16 times less impact resistance than OceaPoly®. Primarily ideal for shallow water vessels that frequently take on damage by debris and rough terrain, OceaPoly® is also great for any watercraft as an extra layer of protection.

OceaPoly® Benefits

- No Mechanical Fasteners - Eliminates water leaking into the boat because of holes drilled for mechanical fastens

- Vacuum Bag Application - Easy installation

- Long Term Protection - Heat or cold temperatures

- Heightened Epoxy Bond Strength - Against exposure, impact, abrasion, chemicals, and UV

- Recommended Plexus Adhesive - Elongation factor of over 100%

- Additional reinforcement - OceaPoly® strengthens the boat bottom

User Friendly - Easy to install, easy to repair if damaged, easy to remove at end-of-life cycle with sandblaster

OceaPoly® Specifications

- Thickness & Weight - 0.25" (1/4 inch), 1.625 lbs. per sq. in.

- Material & Weight - Fiberglass, 2.1 lbs. per sq. ft.

Buoyancy - Specific gravity 0.93-0.98

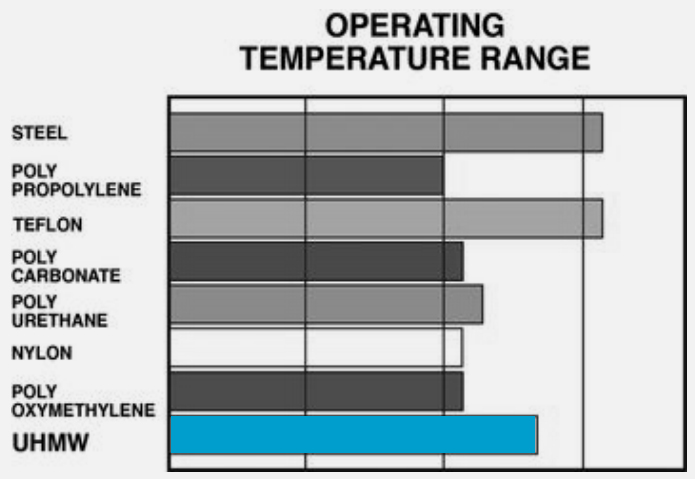

Proven Tolerance - (-60º) to 180º F

- Autoignition Temperature - 662º F (350º C)

- Strength - Bond strength on average is 1058 lbs. per sq. in.

Substrates

Military Grade

A tough product for a tough crew. Helping get the job done.

OceaPoly®is specified on several military application because it’s superior performance over other polymer. According to the US Army Southern Command, US Border Patrol, and the US Coast Guard, OceaPoly® is 3 to 4 times more durable than mechanically fastened UHMW. No holes, no water leaking in boat, no expansion or contraction.

Government Testing Performed with OceaPoly®

United States Army Corps of Engineers

- Wicket Gate Test - Fiber Reinforced Polymer Composite Wicket Gates

- Abrasion Test - Abrasion-Resistant Polymer Composite Overlays & Coatings

- Dam Gate Test - Polymeric Slides to Replace Rollers on Hydraulic Gates & Valves

United States Navy

- Department of Defense - M80 Stiletto

- US NAVY - Submarine Camel

Become a Certified OceaPoly® Installer.

Ask us about our OceaPoly® Installer Program and join our installer network today.

Or, find a professional Certified OceaPoly® Installer in your area.